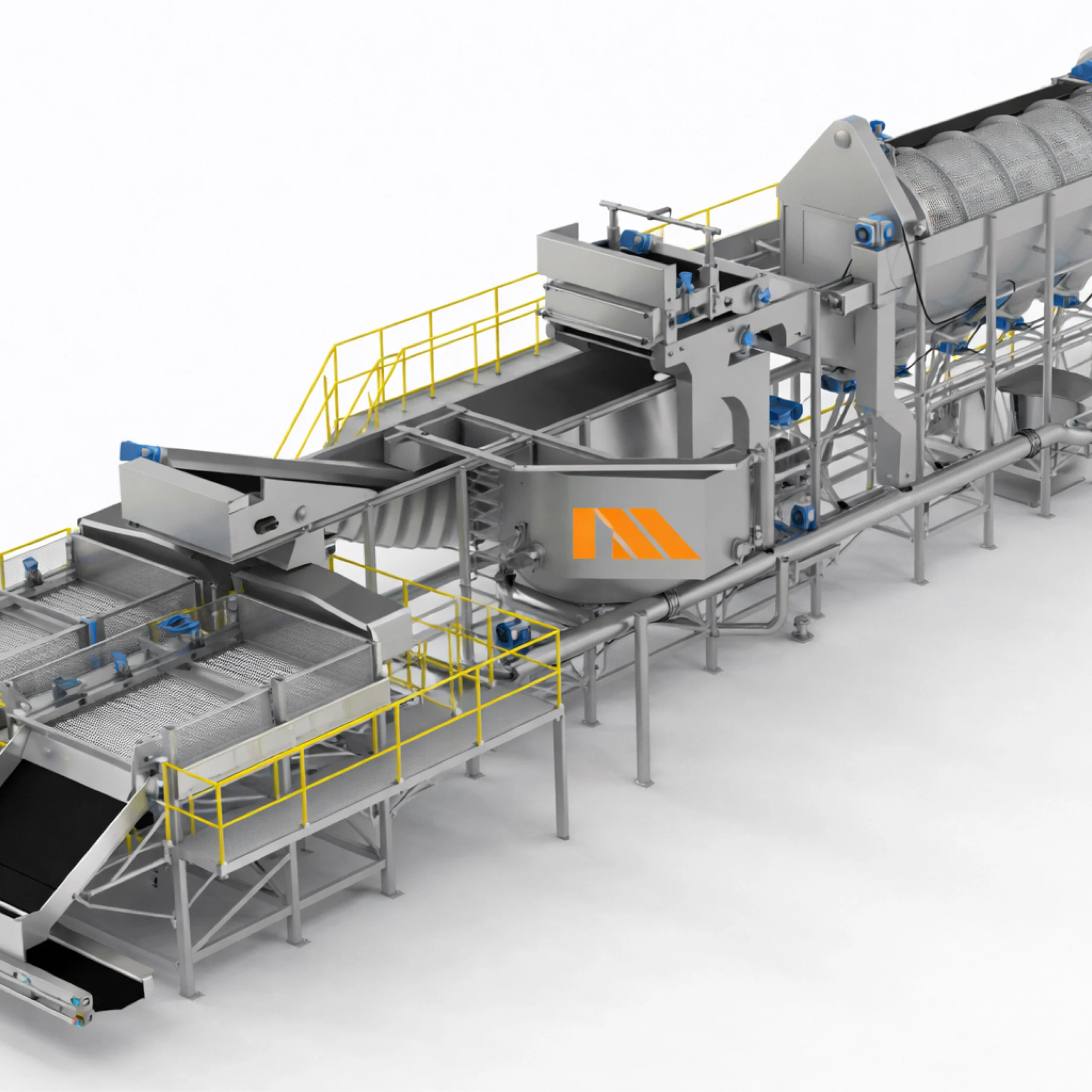

Fully Automated, Touchless Production Line

Every step — from washing to drying — runs on high-precision automation.

No human contact. No contamination. No inconsistency.

What this ensures:

- Uniform quality in every batch

- Higher hygiene and food safety

- Faster production with minimal error

- Reliable supply for large-scale buyers