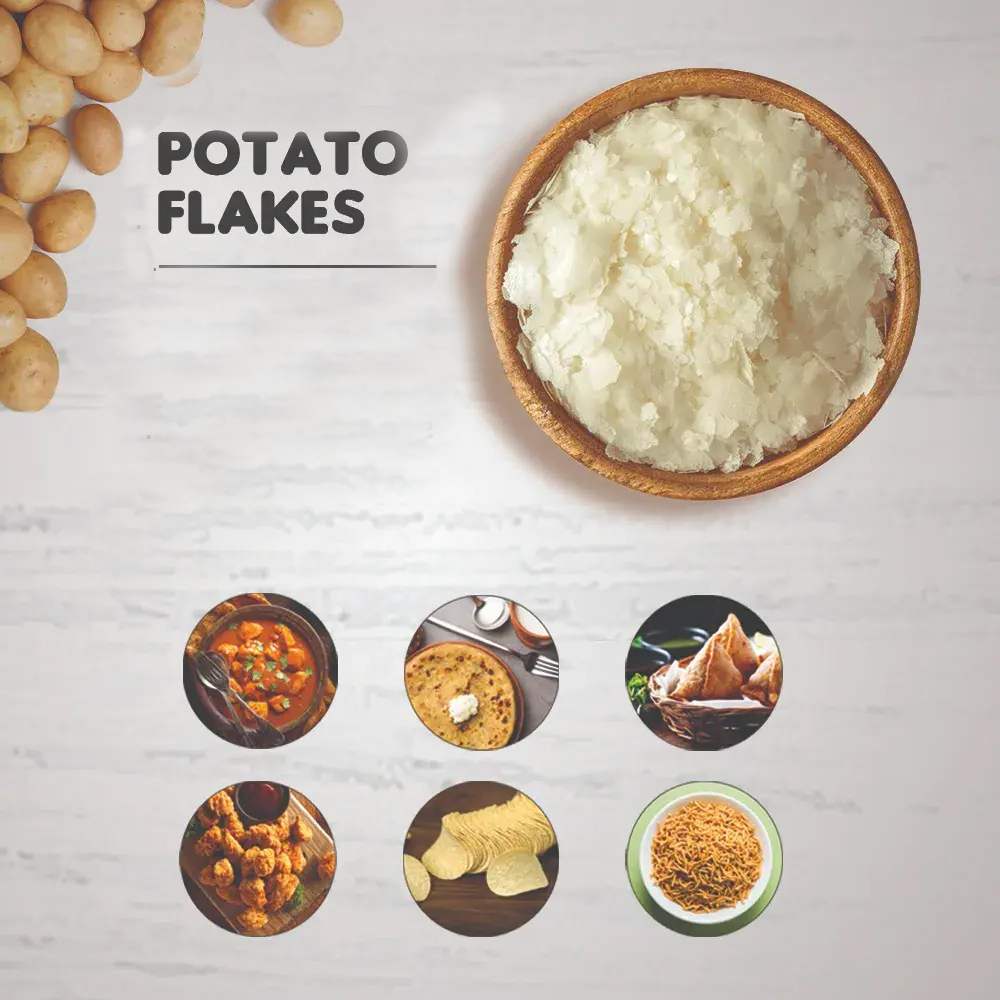

Welcome to Grover Food, the leading potato-to-flakes producing company. Grover Food has emerged as one of India's leading manufacturers of potato flakes, catering not only to the food industry but also to well-established companies in the Motor Dealership and soap manufacturing sectors. After careful scrutiny and extensive research, the Group established Grover Food as a specialized entity for producing high-quality flakes from potatoes.

The company has invested in an ultra-modern plant in Bareilly, Uttar Pradesh, which adheres to European standards and is equipped with imported machinery. In its very first year of operation, Grover Food made a remarkable impact by introducing world-class potato flakes to the Indian market, benefiting both consumers and potato farmers alike. These versatile flakes find application in a wide range of baked and extruded snack products, while also serving as an excellent binding and thickening agent for bakery items.

Read More

We collect fresh potato from the trusted sources to ensure optimum product quality, these potatoes are harvested under strict quality control and stored in high-tech cold storages to stable the various parameters and these also ensure round the year supply to our manufacturing facility. We carefully select our potatoes, so that potato flakes quality remains constant.

Once potatoes reach the facility, they passed through metal detectors and then it is washed with a high-pressure jet which removes dirt and foreign material. This makes inspection easy for damaged potatoes, rotten potatoes and undersize potatoes. This all are removed before they enter into the processing line.

After washing & inspection potatoes are peeled by peelers, to remove the upper skin of potatoes, After peeling they once again washed to remove peel waste. This potato peel waste is used in cattle feed as they have rich nutritional value.

After peeling potatoes are cut in the desired size by high-tech cutters and then enters into specially designed cookers for cooking. This cooking is done with high-pressure steam. To make sure potatoes cooked evenly without losing any nutrients, no water used during the entire process.

Cooked potatoes are then passed through mashers, this masher mash the cooked potatoes in fluffy mass. Additives are added at this point which ensures the long shelf life of the product in the natural condition.

Mashed potatoes are then enters into industrial high-tech dryers, this dryers evaporate the moisture from the mash and form the flakes of potatoes. These flakes are then ground to obtain the desired particle size.

Potato flakes are shorted with particle size and density and then packed in 25 Kg. of paper bag lined with food grade virgin plastic packing to keep moisture away.

At Grover Food, we pride ourselves on our commitment to creating value at every stage of the potato flakes production process. To achieve this, we have implemented a contract farming model that ensures we source the highest quality potatoes from dedicated and skilled farmers. We believe in fostering close relationships with our farmers, and work hand in hand with them to continually improve the quality of their crops. To achieve this, we have enlisted the services of Agro Experts who provide invaluable training to our farmers, helping them to adopt farming practices that are in line with global standards. This investment in our farmers pays off in spades, as we are able to consistently produce high quality potatoes that meet the needs of our customers throughout the year.

We give utmost importance towards the packaging of whole assortment.....

Our products are extensively tested on well-defined parameters to ensure a flawless finish.....

Since the commencement of our business, we have maintained a sound infrastructure base.....