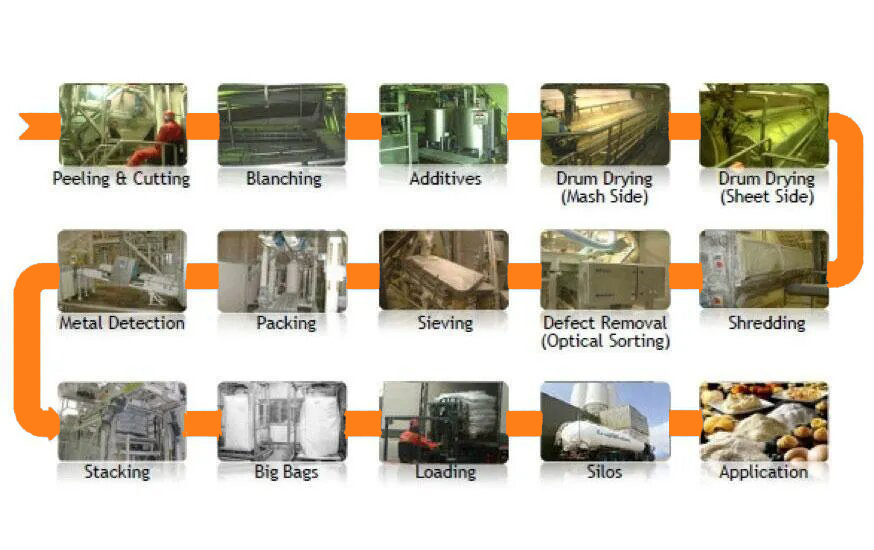

Our Sophisticated Manufacturing Plant

Grover Food has a dedicated team of experts who undertook thorough research to collect information about the finest machinery & equipment available worldwide for the proposed manufacturing activities. For potato products, the comprehensive research done by the team helped us to set-up an ultra-modern manufacturing unit in Bareilly, Uttar Pradesh. Most of the machinery & equipment employed at the flake processing plant are imported from the leading manufacturers in Europe.

We believe in offering the best quality products to our customers and strive to achieve this by utilizing cutting-edge technology in every aspect of the manufacturing process. Besides, the weemphasizes the post-purchase maintenance of the machinery to ensure that product quality never gets compromised in any way.